Cross Cut Machine FP-800 for boards

The cross-cut saw is an efficient and precise solution for automatically cutting boards to specified lengths. It works perfectly with horizontal sawmills, enhancing the efficiency of the wood processing workflow. It replaces traditional cross-cutting, which was previously performed manually by an operator using a chainsaw. As a result, it eliminates the need for manual board formatting, increasing productivity, safety, and cutting precision.

How does the machine work?

✅ After being cut on a horizontal sawmill, the board is automatically transported to a belt conveyor, which then moves it to powered roller conveyors.

✅ The cross-cut machine operator can select the desired cutting length

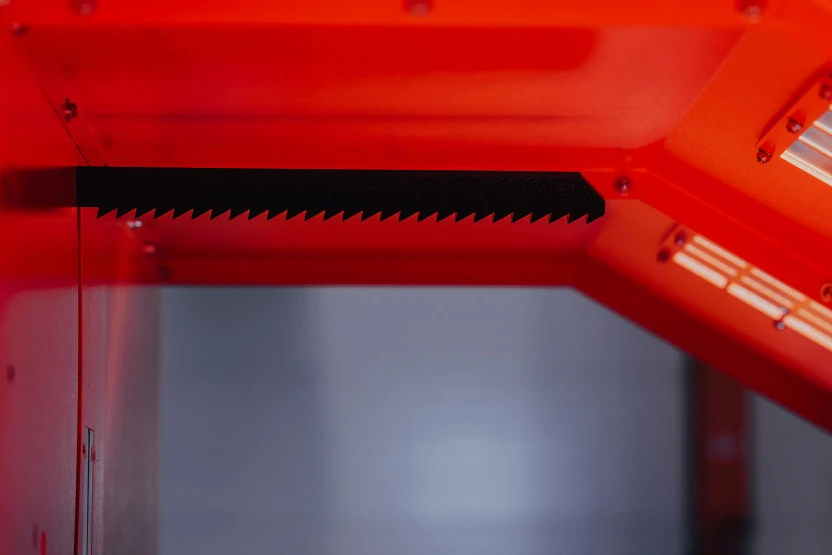

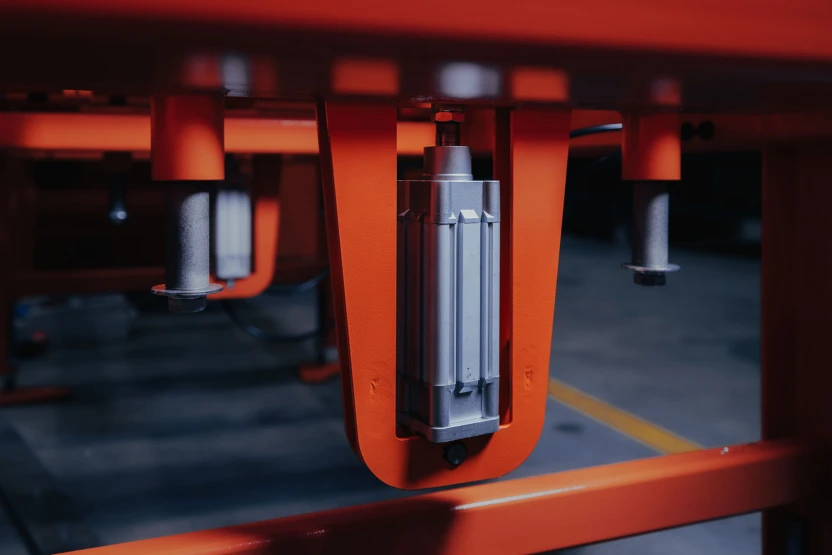

✅ Retractable stops on the roller conveyor position the board, ensuring accurate and repeatable cuts.

By utilizing modern technology, this machine enables fast and efficient production, minimizing waste and increasing the profitability of the sawmill.

Technical data

| Dimensions |

|

| Weight | 500 kg |

| Dimensions of infeed workpiece |

|

| Main motor power | 6,5 kW |

| Power supply | 230/400 V |

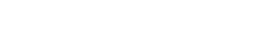

| Cutting head | Pneumatic horizontal movement of the circular saw head |

| Workpiece down-holder | Pneumatic |

| Controls | Semi-automatic |

| Operator control panel | Fitted on the frame of the Cross-cut saw |

| Circular blade diameter | 450 mm |

| Other information |

Cutting variants tailored to individual needs, depending on:

|

Optional equipment

- infeed roller conveyor

- outfeed roller conveyor with bumpers determining the formatting length

- outfeed roller conveyor with bumpers determining the formatting length and a sorting function for cross-cut boards