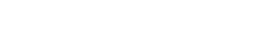

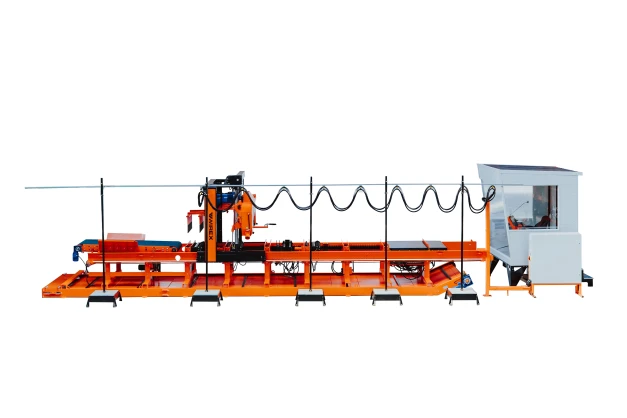

CZ-1/XS petrol-powered sawmill

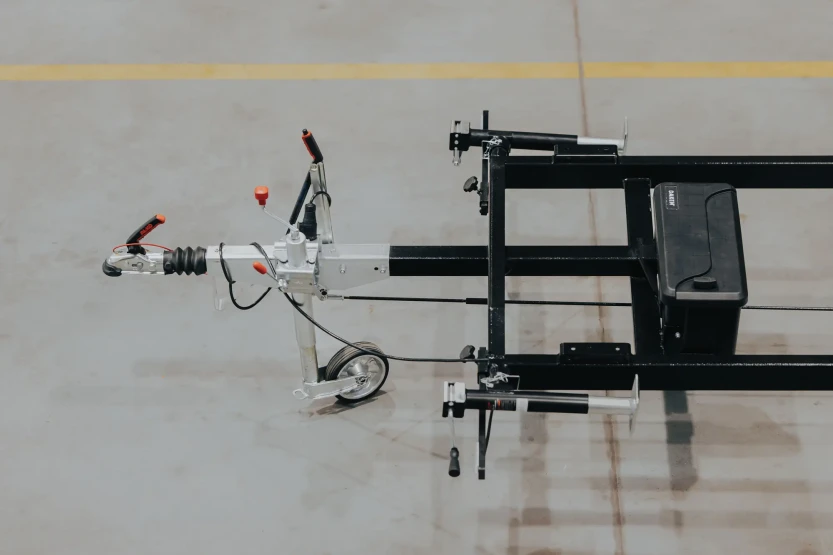

This machine is a simplified model of a band sawmill with manual log manipulation and without the option of hydraulic devices. Due to a wide range of optional equipment, the CZ-1/XS sawmill is a versatile wood-working machine that can be upgraded according to the intended working profile or one's budget. What makes this model special is that even after the purchase, it is always possible to expand the equipment, leading to an expansion of production capacity. This sawmill s available in two variants: gasoline or elecro powered.

This machine is a simplified model of a band sawmill with manual log manipulation and without the option of hydraulic devices. Due to a wide range of optional equipment, the CZ-1/XS sawmill is a versatile wood-working machine that can be upgraded according to the intended working profile or one's budget. What makes this model special is that even after the purchase, it is always possible to expand the equipment, leading to an expansion of production capacity. This sawmill s available in two variants: gasoline or elecro powered.

It is an ideal solution not only for hobbyists, carpenters, or farmers who occasionally process logs for their own needs but also for sawmills focused on processing medium-sized wood, with occasional demand for cutting larger diameters – up to 800 mm.

Technical data

| Dimensions |

|

| Weight | 900 kg |

| Log diameter | max. 800 mm (distance between blade guide rollers: 890 mm) |

| Length of cut (standard) | 4600 mm (may be individually extended) |

| Min. thickness of obtained plank | 25 mm last board thickness |

| Main motor power |

|

| Cutting head |

|

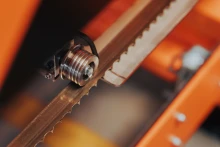

| Band wheels diameter | 475 mm |

| Band saw specification |

|

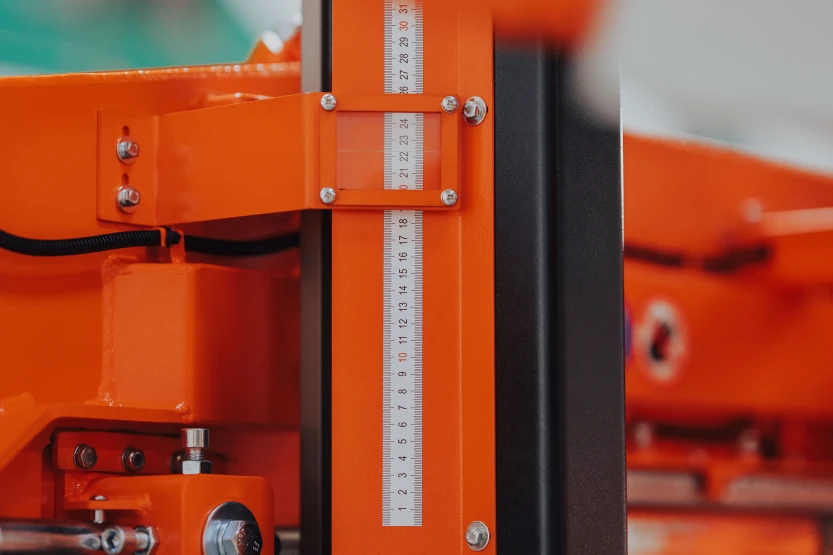

| Blade tension roller slide |

manually adjusted Note: powered option available |

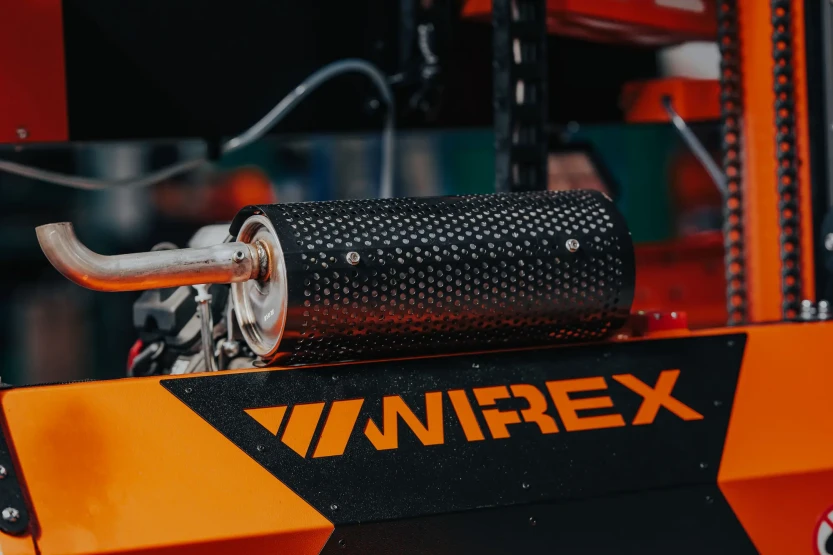

| Thickness of cut setting | manual set on scale |

| Operator control panel | fitted to the moving head rig |

| Workpiece handling |

|

| Capacity per hour | up to 1,5 m3 |

Optional equipment

- bed extension 2,9 m long

- electrical up/down drive of cutting head with thickness of cut controller ISP-010

- electrical up/down drive of cutting head with thickness of cut controller RLI-04

- electrical forward/reverse drive inverter-controlled

- powered adjustable blade tension roller slide

- LED lightining system (3 lamps)

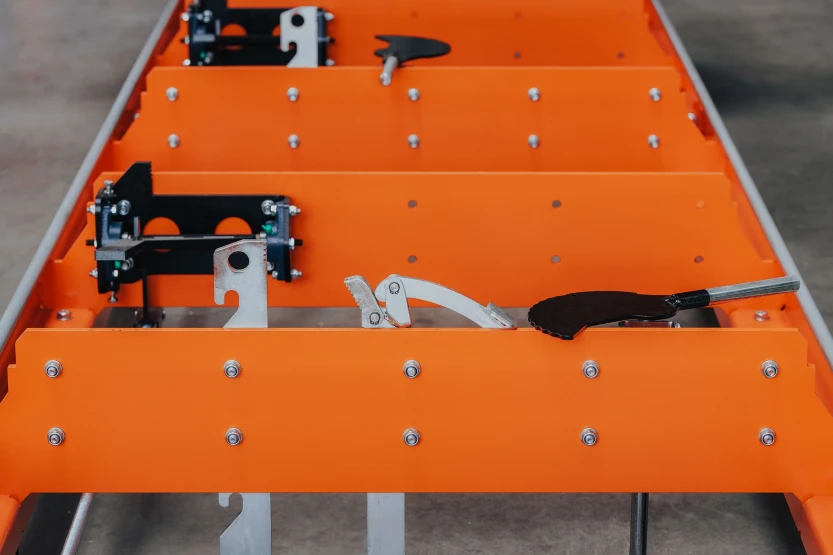

- set of lifted side supports - 4 units

- screwed feet for sawmill frame elevation - 16 units (for basic frame length)

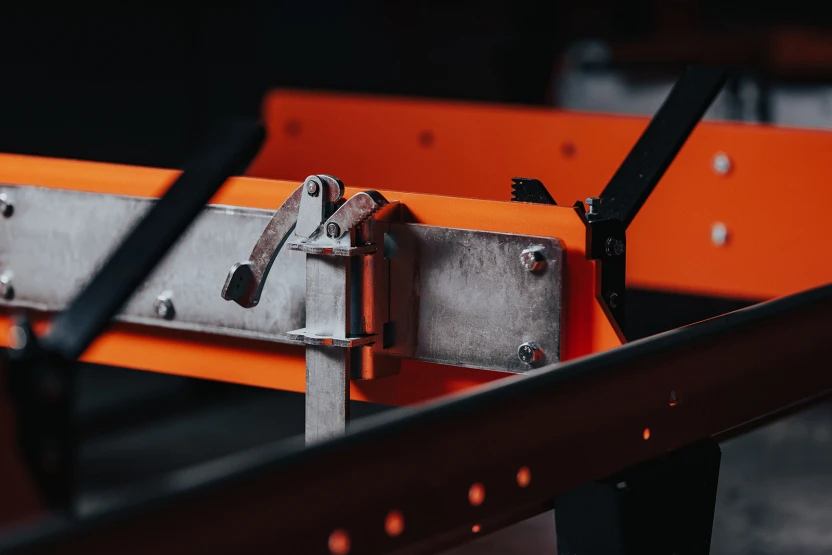

- manual eccentric log clamp

- scissor clamp

- screw clamp

- manual log turner

- manual side support

- manual log levelling roller

- long mounting plate (installation of additional components on the frame)